Slab Ducts – Dark Side Of Dryer Vent Cleaning

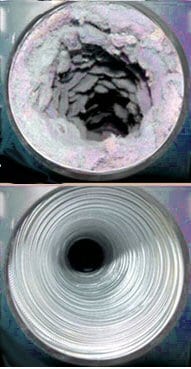

Over the course of the past 25 years, we’ve seen a lot of changes to buildings,  their construction and designs. Dryer vents are no exception. The image most people have of dryer vents are round three to four inches in diameter circular metal pipe with a flap on the end. While this is a common (if not the most common) design, especially for low-rise buildings, there are a number of different configurations that are employed.

their construction and designs. Dryer vents are no exception. The image most people have of dryer vents are round three to four inches in diameter circular metal pipe with a flap on the end. While this is a common (if not the most common) design, especially for low-rise buildings, there are a number of different configurations that are employed.

In a previous E-tips we highlighted that the greatest source of potential damage from uncleaned dryer vents is not fire, but moisture. As the air from the dryer becomes trapped, it condenses the moisture, which collects into pools and starts to wreak untold damage. They permeate into the surrounding concrete, and damage the overall structure. Such leaks tend to spread down to ceiling areas, leaving unsightly watermarks.

This is somewhat more common issue than people realize, particularly in high-rise buildings. Many use a rectangular shaped vent, which is sunk into cement prior to curing. While there is nothing particularly wrong with this design, the issue is with implementation. Often the duct runs are constructed with too many corners, quickly diminish the airflow’s strength. More alarmingly, many are only an inch in depth, which is insufficient to ensure proper air passage. Finally, many are damaged during construction, causing an obstruction that prevents air from passing altogether. We’ve seen all of these issues, and they can be extremely problematic.

Remedial work is often an expensive, and messy proposition. Repairing the concrete ductwork , if it is even an option, can run into the tens of thousands of dollars. The alternative is to build a new duct run with a drop down ceiling. While less costly than concrete reconstruction, it can be aesthetically ugly and diminish a unit’s value.

, if it is even an option, can run into the tens of thousands of dollars. The alternative is to build a new duct run with a drop down ceiling. While less costly than concrete reconstruction, it can be aesthetically ugly and diminish a unit’s value.

While in some cases such work is unavoidable, there are alternatives to deal with these issues. Booster fans can be installed to provide extra airflow to overcome any existing issue. A proper exterior housing that provides no impedance to exiting air can help. In addition, preventative work can do quite a bit to ensure proper airflow. This includes regular cleanings of the system, with particular care for problem units. While this may require a few additional minutes of attention, it can avoid a far more costly repair job.

If you have a problem unit like this, give us a call. We can inspect the system and determine whether alternative approaches can ensure proper function, or major remedial work is required.